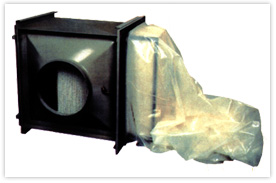

Introduction :In pharmaceuticals many of HEPA. Filters are used for containment, that is on the exhaust side of a critical process. Whose dangerous by product. Such as radioactive particulars, harmful viable organisms or know carcinogen agents must be prevented from entering the atmosphere. When filters become contaminated In service, a method for their removal without direct operator contact is necessary. To protect the atmosphere from carcinogens and harmful contaminant, Bag in, Bag out module are to be used. ‘SIGMA is supplying Bag in, Bag out module with high quality bags For remove of Filters which have collected toxic or potentially dangerous materials during its service life and all tools required for removal of filters.

DISPENSING AND SAMPLING BOOTH (REVERSE FLOW UNIT)

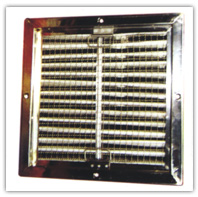

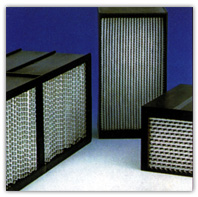

Prefilters:- SIGMA Filters comprising no Woven synthetic / Fire retardant the pre filters and Intermediate Filters made of non woven synthetic Fire retardant media. Specially treated with anti fungal and bactericidal reagents to inhibit growth of micro, organisms. These media is fire retardant, water repellent, and washable type.

Pre filter EU – 5 grade type having eff. 40-60% on Eurovent std. and intermediate filter is EU-7 grade type. Laving eff. 80%-90% on eurovent std.

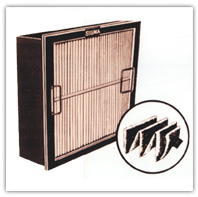

Final Filter:- These filter is minirleate separatorless HEPA filter or Absolute filters with aluminium separators. Having eff. rating 99.97% down to 0.3 micron when tested as per IES-Rp-cc-001 -86 std. Operation and cleanliness level

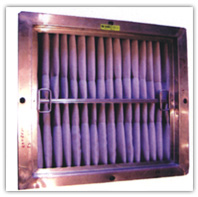

Ambient air is drawn in through a prefilter & intermediate filter on the top of cabinet and introduced in the work zone through the HEPA filter. The average velocity in the work zone is maintained between 0.45 m/sec to 0.65 m/sec. Air cleanliness in the work zone is better than class 100.in accordance with U.S. FED. Std. 209 E.

Motor, Blower, Fans :- High Performance noise abated, statically and dynamically balanced impellers, Dual outlet blower assembly. Statically and dynamically balanced, direct driven type motor. Fans are mounted on vibration isolation mounts to minimize vibration.